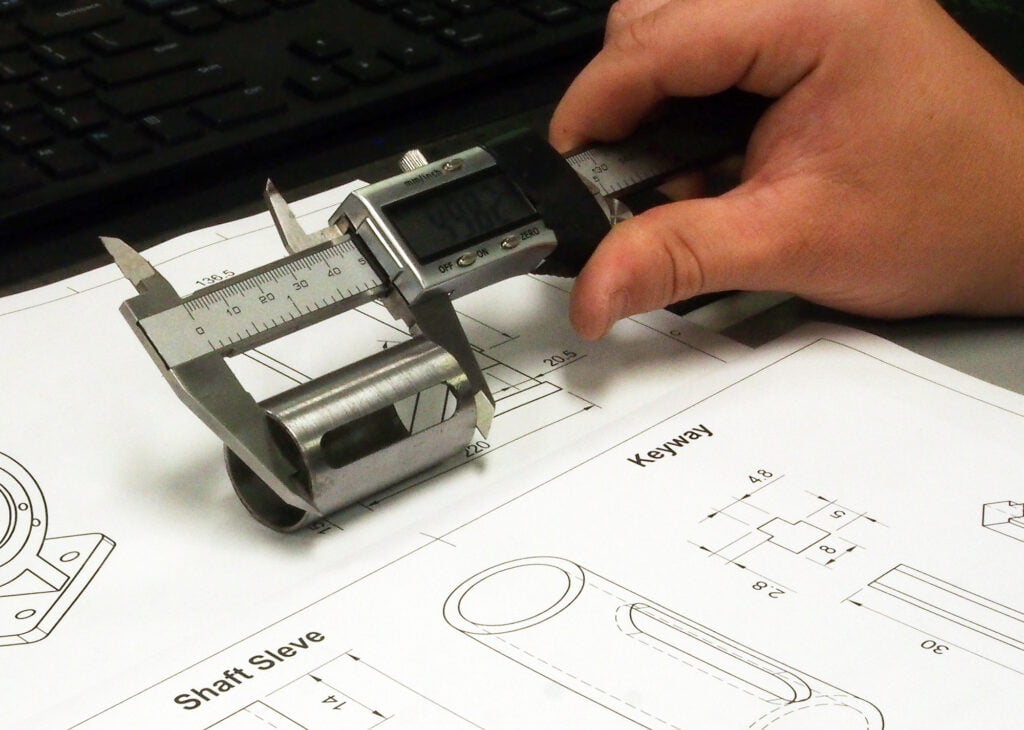

Custom Builds

Design & Develop

The team at Pumps Australia are regularly designing and developing new products as per customer requests or for the marketplace to help the industry develop further with better technology.

To enquire about our new product development contact us today.

Custom specifications

You think it, we will build it. Need something that isn’t in our range?

No problem, we are also able to custom design and build products that suit your application or specifications. All you need to do is provide us with an outline of what you are trying to achieve, and we will custom build a solution. From design, fabrication, assembly and testing, we can deliver a pumping solution for most situations. We are able to provide this service as we have a huge inventory of components such as; nozzles, hoses, pumps, frames, engines and hose, in stock and we are able to assemble these into a system that will suit you. Even if we don’t stock the right components you need, through our diverse range of suppliers and broad knowledge of pumping products, we will provide a solution. With over 25 years’ experience and expertise, you can rely on us to make sure our custom units are fit for your purpose and of the highest quality.

Some of the projects we have undertaken include;

- Trailer mounted units with specific mine site specifications

- EXD rated hydrostatic testers

- Solar powered, radio controlled, bitterns gates

- Dewatering units

- Pump sets

- 10,000 psi Harben Jetter

Some customers we have supplied customised products to include: BHP, Rio Tinto, FMG, Downer, Thiess, Water Corporation, Shires and Councils, Citic Pacific, Wheatstone, Snowy Hydro, Onslow Salt. We also specialise in petrol, diesel, electric, hydraulic and air driven pumping solutions, including EXE explosion proofing and have experience in;

- Hydrogen compressors

- Boiler feed pumps

- Steam turbines

So, if you need a special system designed and built to your specifications, contact us today so we can help you with a solution.

Design Team

Our Award-winning design team have been designing customised pumping solutions for our clients for over 20 years. Our designs not only incorporate the best quality materials and products but also consider your budgetary constraints.

Fully Qualified Technicians

Our workshop consists of fully qualified electricians, metal fabricators, diesel and petrol mechanics and fitters. With over 50 years combined experience. This means your unit is built and commissioned with the highest of quality.

Australian Sourced Materials

Where we can, we source all the materials used in constructing our skids, frames & buggies from Australia. In particular, Australian steel used, is locally sourced, galvanised and powder coated to help prolong the life of your custom made unit.

First Class Engines & Motors

Using only first class engine brands such as; Honda, Yanmar, Kohler, Hatz, Deutz, this helps to ensure reliability.

European Pumps & Accessories

We source all of our High Pressure Pumps & Accessories from several world leading European manufacturers.

Worldwide Delivery

Pumps Australia work with multiple shipping companies, local, national and worldwide. We can ship your unit anywhere in the world.

Frequently Asked Questions

Is It Bad to Run The Pump Dry?

Absolutely. The centrifugal pump shaft and impeller are spinning at extremely fast rates. With no water flow to transfer their rotational energy, that energy is released as heat instead. So, the pump will get very hot. If the pump is run dry, its moving parts, mainly the mechanical seal or shaft packing will fail and excessive seal leakage will occur.

What is the Difference between ISO & DIN Pumps?

Both ISO & DIN pumps are heavily used in circulation and transfer applications around the world due to their reliability and in expense while able to achieve high flow rates and high heads.

But what is the difference?

- ISO- International Standards Organisation

- DIN – Deutsches Institut für Normun

Due to their standards being different, DIN pumps & ISO Pumps wont align in their heights, widths or lengths.

But the most standout point between the two is the inlet and outlet flanges.

We can supply both ISO & DIN pumps for your desired application.

What is the Difference between EXE & EXD?

EXD – Flameproof Enclosure – The protection concept is to contain the explosion and prevent the flame propagation. Following the protection is pure mechanical, i.e. strength of housing and the installation and maintenance of functional flamepaths to avoid flame propagation.

EXE – Increased Safety – The protection concept is to avoid all arcs, sparks or hot surfaces. This protection is more sophisticated and explosion integrity is taken care of by manufacturer.

Why Isn't My Pump Pumping?

Whether it’s your centrifugal or pressure cleaner pump, here could be several factors behind this.

Firstly, 90% of pumps fail due to poor suction conditions. Some of the other factors are as follows;

Pressure cleaner pumps;

- Lack of water

- Dirty water

- Hose leaks

- Poorly fitted hose clamps

- Blocked filters

- Lack of maintenance

Centrifugal pumps:

- Lack of water

- Incorrect hose size (suction and discharge)

- Exceeding suction design capabilities

- Poorly fitted hose clamps (suction side)

Additionally, if you are using pipes that are too small or have too many elbows, this can also cause issues. Pumping water through small diameter pipes (and pipes with elbows and check valves) increases the water pressure (called friction loss), but as a result also increases flow resistance. If the resistance is too great, your pump will not perform.

What Causes Centrifugal Pump Cavitation?

When the inlet pressure of a water pump falls below pump design specifications, tiny vapor bubbles can form in the water around the eye of the impeller.

When the water containing these bubbles is forced into a high pressure environment on the other side of the impeller, these bubbles collapse, thereby creating tiny shock waves and points of high pressure. These shock waves can actually corrode the surface of the impeller.

To prevent cavitation, always be sure to operate your centrifugal pump within its pressure and flow specifications. 90% of pumps will fail due to issues such as hoses, fittings and clamps not being fitted correctly which results in poor suction.

Get in touch today

Sign up to our newsletter

"*" indicates required fields

Copyright © 2023 Pumps Australia Pty Ltd. All rights reserved. Sitemap.

Web Design by Cloud Cartel